Showing all 84 results

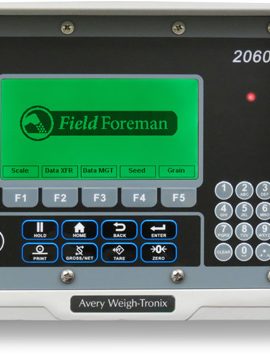

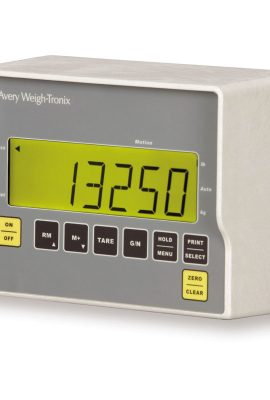

2060 Multi-purpose Indicator

The 2060 indicator is a fully programmable indictor that can be tailored to fit your needs. This simple to use weight indicator is factory loaded with a Standard Weighing Application that encompasses all the great features of the general purpose 640 Indicator, but with enhanced capabilities and the ability to add application specific software. Industry leading technology is paired with a simple, user friendly interface to fit every application on the farm.

The 2060 Indicator has optional Field Foreman Application Software and Farm Foreman PC Software – From seed to grain, one indicator, two seasons. Field Foreman provides powerful, user friendly scale software for grain carts and seed tenders. Easily and efficiently track all planting and harvest transactions while taking advantage of key standard features including SmartLoad automatic grain cart load tracking. Farm Foreman PC software allows you to easily transfer data between an indicator and a PC, providing comprehensive harvest and planting analysis and reporting at the touch of a button.

Literature

35901 Load Foot

The 35901 load foot is for use with shear beam load cells in applications such as platform scales in harsh environments.

Consisting of stainless steel and rubber (elastomeric) parts, it provides a stable base for the load cell and ensures the load is applied in an optimum manner. It is ideal for use in harsh industrial environments where dirt and dust can be present, as the rubber cover gives protection to the articulating ball joint.

Key features

- Capacity range: 300-2500kg

- Stainless steel and rubber (elastomeric) components

- M12 connection

- Covered swivel joint

- For use with shear beam load cells T85 and T85-N

Typical applications:

- Multi-cell platform scales

Literature

35917 Load Foot

The 35917 load foot is for use with high capacity shear beam load cells in applications such as platform scales in general industrial environments.

Consisting of stainless steel and rubber (elastomeric) parts, it provides a stable base for the load cell and ensures the load is applied in an optimum manner.

Key features

- Capacitiy range: 3000-5000kg

- Stainless steel and rubber (elastomeric) components

- Large, stable base plate of diameter 140mm

- For use with shear beam load cell T85 of capacity 3000kg and 5000kg

Typical applications:

- Multi-cell platform scales

Literature

640

The Model 640 is a general purpose indicator which provides simple, yet accurate and reliable weighing used on mixers, grain carts (grain chasers), livestock scales, feed bins, weigh carts and many more applications.

- Simple Operation – ZERO key zeros the scale, PRINT key transfers weight data to printer, computer, or transfer data module (TDM-40)

- Gross/Tare/Net – G/N key allows viewing of either gross or net weights. TARE key is useful for temporary “zeroing” of the scale

- Motion Filtering – Enhanced dual “harmonizer” filtering settles down weight display for easy viewing. Ideal for filtering excess motion on mixers and livestock applications

- Memory Accumulators – 100 six-character alpha-numeric accumulator channels. Useful in identifying fields, seed type, livestock groups or amounts of recipes batched and or fed

Literature

640M

NEW Compact Design…

The Model 640M is a “Miniature” general purpose indicator which provides simple, yet accurate and reliable weighing used on mixers, grain carts (grain chasers), livestock scales, feed bins, weigh carts and many more applications.

The small, compact indicator design makes it ideal for places like truck and tractor cabs where space is limited (size: 5.5″H x 7.25″W x 3.25″ D).

- Simple Operation – ZERO key zeros the scale, PRINT key transfers weight data to printer, computer, or transfer data module (TDM-40)

- Gross/Tare/Net – G/N key allows viewing of either gross or net weights. TARE key is useful for temporary “zeroing” of the scale

- Motion Filtering – Enhanced dual “harmonizer” filtering settles down weight display for easy viewing. Ideal for filtering excess motion on mixers and livestock applications

- Memory Accumulators – 100 six-character alpha-numeric accumulator channels. Useful in identifying fields, seed type, livestock groups or amounts of recipes batched and or fed

Literature

640XL

The Model 640XL is a general purpose indicator which provides simple, yet accurate and reliable weighing used on mixers, grain carts(grain chasers), livestock scales, feed bins, weigh carts and many more applications.

- Simple Operation – ZERO key zeros the scale, PRINT key transfers weight data to printer, computer, or transfer data module (TDM-40)

- Gross/Tare/Net – G/N key allows viewing of either gross or net weights. TARE key is useful for temporary “zeroing” of the scale

- Motion Filtering – Enhanced dual “harmonizer” filtering settles down weight display for easy viewing. Ideal for filtering excess motion on mixers and livestock applications

- Memory Accumulators – 100 six-character alpha-numeric accumulator channels. Useful in identifying fields, seed type, livestock groups or amounts of recipes batched and or fed

Literature

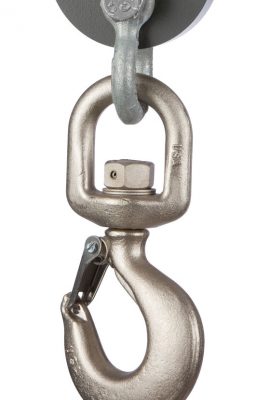

AP Crane Scale

Dillon AP Mechanical Crane Scales are available in capacities from 500 to 20,000 lb and 500 to 10,000 kg. Every detail of their construction was chosen for long life. Uncomplicated operation includes tare function and maximum peak load indication. AP Crane scales are made up of two parts, an AP Dynamometer and the associated crane scale hardware kit which includes the following: a swivel hook, oversized shackle assembly and a wooden shipping/storage crate.

Product Features

- Now offered as an add on feature to the AP Dynamometer of choice

- Available in Low, Intermediate and High Range Models

- Large safety factor for overload protection and long life

- No batteries required

- Dial size choice for the best in portability or visibility

- Anti-parallax dial and pointer produce accurate readings from any perspective

- Maximum hand retains peak load point and is easily reset

- High strength case resists heavy blows

- Generous shackle openings mate with most hooks and hardware

- Off set load beam eases tension measurement

Product Specifications

- Capacities:

- From 1,000 to 20,000 pounds

- From 500 to 10,000 kilograms

- Accuracy:

- + 0.5% of capacity

- Temperature Range:

- -50° to 140° F | -45° to 60° C

- Construction:

- Pressure bar: High-grade E4340 alloy steel or 7075-T651 aluminum

- Shackles: A4140 forged steel (machined from E4340 steel)

- Shackle pins: Machined from E4340 steel

- Case Housing:

- 5″ models are equipped with high strength composite plastic case

- 10″ models use cast aluminum enclosure

- Corrosion Protection:

- Pressure bar protected with durable powder coat paint

- Shackles and pins are electroless nickel plated

- All integral machining and fasteners are produced from noncorrosive materials or have suitable plating

AP Dynamometer

Originally designed to measure the tension on telephone wires, the AP Dynamometer has proven to have limitless versatility as a tension and weight measuring instrument. It is used for such diverse jobs as suspended weighing, mounting cables for bridges, adjusting tension on guy wires, field testing chain and rope as well as wire. Basically anything requiring precision force or tension measurement.

Dillon is the leader in dynamometers with the largest installed population throughout the world. The sturdy design, top grade components and premium coatings make it last for years in severe environments and applications: the pounding aboard military vehicles, rough handling in field measurements and even use underwater (Dillon recommends short intervals in clean water followed with rinse and drain). Embraced by industrial contractors across the globe, we are confident the AP will satisfy your most demanding applications.

Product Features

- Broadest range of capacities and resolutions are certain to fit your needs

- Large safety factor for overload protection and long life

- No batteries required

- Dial size choice for the best in portability or visibility

- Anti-parallax dial and pointer produce accurate readings from any perspective

- Maximum hand retains peak load point and is easily reset

- High strength case resists heavy blows

- Generous shackle openings mate with most hooks and hardware

- Off set load beam eases tension measurement

Product Specifications

- Accuracy:

- + 0.5% of capacity

- Temperature Range:

- -50° to 140° F | -45° to 60° C

- Construction:

- Pressure bar: High-grade E4340 alloy steel or 7075-T651 aluminum

- Shackles: A4140 forged steel (machined from E4340 steel)

- Shackle pins: Machined from E4340 steel

- Case Housing:

- 5″ models are equipped with high strength composite plastic case

- 10″ models use castaluminum enclosure

- Corrosion Protection:

- Pressure bar protected with durable powder coat paint

- Shackles and pins are electroless nickel plated

- All integral machining and fasteners are produced from noncorrosive materials or have suitable plating

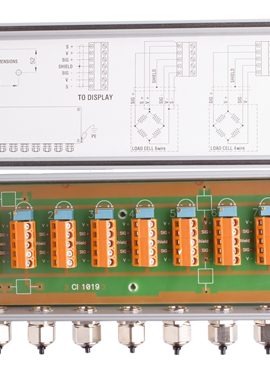

ATEX Junction Boxes

With Thames Side’s ATEX approved junction boxes, load cells in hazardous areas can be connected to the amplifier/indicator simply and cost-effectively

Our ATEX junction boxes have hermetic sealing that provides IP66 ingress protection.

To create a complete weighing system (measuring chain) the junction box must be connected to an indicator/transmitter etc. We offer specially designed durable polyurethane cable can be in custom lengths, in 4-wire or 6-wire configurations.

Key features

- 5 year warranty

- 4-cell or 8-cell versions

- Trimming potentiometers as standard

- Aluminium construction

- Approved for all zones (0, 1, 2, 20, 21, 22)

- IP66 protection

- Stainless steel versions available on request

Literature

B140 Counting Scale

The B140 is an advanced higher accuracy counting/coin scale with increments for good resolution on small counted parts.

Dual functionality counting scale

The B140 has a 30 kg / 60 lb capacity enabling it to function either as a counting scale or coin counter.

Additional flexibility

Operates on either US/UK/EU power supplies (all included) or a built-in rechargeable battery.

It features three bright LED displays with three brightness levels and a rugged ABS plastic base with stainless steel weight platter.

Literature

BS Diamond Series Bench Scale Base

Diamond Series bench scales are built to the highest specification for dependable industrial weighing. They are designed to be tough and long lasting, with no moving parts for outstanding reliability. Their design also protects against overloading or objects dropped on the scale.

Suitable for a range of applications

The BS Diamond Series bench scales are available in both carbon steel and stainless steel, with a ball top option for integration into conveyors, making them suitable for a range of applications.

Wide range of weighing capacities available

These dependable bench scales come in a variety of sizes and capacities, from 30lb to 500lb (15kg – 250kg) to suit each application.

Ideal bench scale for heavy washdown environments

The NSF ANSI3A certified, fully stainless steel Diamond bases are IP69K rated, making them ideal for heavy washdown environments, particularly in the food and beverage industries.

BSF Torsion Bench Scale base

The BSF Torsion bench scale base is designed to be paired with a weight indicator to form a simple industrial weighing system.

Ideal for food and heavy washdown environments

Certified by NSF to NSF/ANSI Standard 3-A, the torsion base BSF and BSG are ideal bench bases for use within all types of food environments

These fully stainless steel bench scale bases are washdown and corrosion resistant, making them ideal for food and food processing industries.

Extremely tough and reliable bench scales

The Torsion bench scale bases can stand the abuse of a busy industrial environment with minimal maintenance. Their 500% overload protection and breakaway load transfer system, which protects the weight sensor, makes these bench scale bases inherently tough and dependable.

The Torsion bench scale bases are particularly rugged by design – engineered to resist overloading and sudden dropped loads.

Literature

BSG Torsion Bench Scale Base

The BSG Torsion Bench Scale Base is designed to be paired with a weight indicator to form a simple industrial weighing system.

Ideal for food and heavy washdown environments

Certified by NSF to NSF/ANSI Standard 3-A, the torsion base BSF and BSG are ideal bench bases for use within all types of food environments

These fully stainless steel bench scale bases are washdown and corrosion resistant, making them ideal for food and food processing industries.

Extremely tough and reliable bench scales

The Torsion bench scale bases can stand the abuse of a busy industrial environment with minimal maintenance. Their 500% overload protection and breakaway load transfer system, which protects the weight sensor, makes these bench scale bases inherently tough and dependable.

The Torsion bench scale bases are particularly rugged by design – engineered to resist overloading and sudden dropped loads.

Literature

BSQ Bench Scale Bases

Now available in a range of high capacity 80kg and 35kg and low capacity 1kg and 5kg models.

Unrivalled Accuracy

The BSQ is a highly accurate digital bench base with over 1 billion internal counts and a readability of over 3.5 million divisions (unapproved). In practice, this means that the BSQ can detect even the tiniest of weight changes with astounding precision.

Featuring the very latest state of the art suspended Quartzell technology, the BSQ guarantees repeatable balance accuracy at all times.Small and large items can be weighed on a single base, allowing one scale to do a job that might previously have required several. With a fast return to zero between readings, the BSQ provides the speed and repetitive accuracy that can be vital in situations where highly accurate weight readings are required.

When used with our ZM400 series indicators, the BSQ bench base can accurately display down to 0.01g, giving balance accuracy but with the strength required for use in an industrial environment.

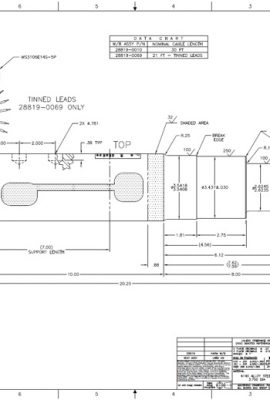

Customised Load Pins

Strain gauged load pins can easily replace an existing clevis, pivot pin or solid shafts in machinery or equipment to measure the load at that point.

Key features

- Custom manufactured to replace existing pins, normally without changes to the existing mechanical structure

- Robust construction in high strength stainless steel, with optional material certificate to EN 10204 3.1B

- Choice of locking/retaining options to suit your application

- Fast delivery with CAD drawings supplied for approval prior to manufacturing

- Externally gauged for IP66 or internally gauged for IP68 protection

- Operating temperature from -20˚C to +90˚C

- High temperature option for use up to 180˚C

- Optional integrated 4-20mA amplifier for analogue outputs

- Single or dual (redundant) output options available

- ATEX option

- SIL 2 / SIL 3 safety rating options

Typical applications:

- Overload protection devices

- Load monitoring and safety systems

- Cranes, hoists and other lifting equipment

- Pivots and load shackles

- Load limiting systems, e.g. in conveyors

- On-board weighing in trucks, trailers and mobile machinery

- Marine applications, e.g. mooring lines and winches

- High temperature weighing and load monitoring systems

- Load monitoring and overload protection in hazardous areas (ATEX)

Literature

Digital J-Box System – ZB210

The ZB210 is the Avery Weigh-Tronix digital junction box for new and existing truck scale, floor scale and batching applications. Designed to meet the rigors of outdoor and industrial environments, the ZB210 can be retrofit into an existing scale system, regardless of the original manufacturer.

Suitable for up to 16 sensors

Receive inputs from up to four analog weight sensors, or daisy chain multiple ZB210s to process up to sixteen sensors.

Faster install & calibration

Inputs from analog weight sensors are individually converted to digital readings, resulting in faster, more precise installation and calibration so your scale is ready to use sooner. Share calibration and weighing information across the system.

No signal loss

Because the signal is digital, you can use longer cable runs with no signal loss or go wireless for added convenience.

Increased uptime

By recording performance history and mechanical issues, you’re able to increase your scale’s uptime through improved diagnostics to schedule maintenance before a repair is needed.

The ZB210 Digital Junction Box is available in two different form factors. For indoor applications, choose either the ZB210-SG or ZB210-LG. For outdoor applications such as truck scales, choose the ZB210-STVS which provides additional protection against severe transient voltage strikes.

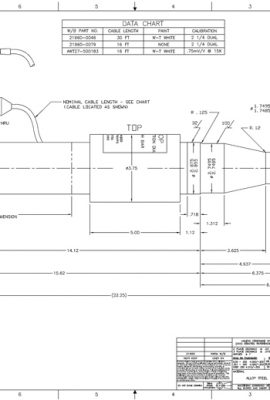

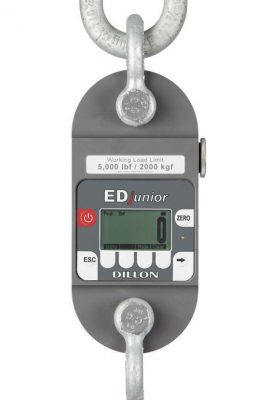

EDjunior Crane Scale

The Dillon EDjunior Crane Scale is all about value. Behind its simple design and easy operation, you will find the quality and performance not found elsewhere. With the EDjunior Crane Scale, Dillon proves that economy can go hand-in-hand with accuracy, long service life and, most importantly, worker safety.

EDjunior Crane Scales are made up of two parts, an EDjunior Dynamometer and the associated crane scale hardware kit which includes the following: a swivel hook, oversized shackle assembly & a wooden shipping/storage crate.

Click here to view product dimension

Click here to view available shackle dimensions

Click here to view available hook attachment dimensions

Product Features

- The EDjunior provides peak detection as well as sustained load readings

- The load element design and strain gauges chosen for the EDjunior produce an accuracy of 0.2 % (full scale)

- Readings are displayed with a resolution of 1 part in 1000 to ensure the level of readability required for critical lifting applications

- The exclusive Dillon SOFTKEY interface provides direct access to setup and display functions without the typical confusing menu structure

- With the EDjunior’s low power consumption, typical battery life is over 425 hours

- Dillon’s distinctive curve-body design further eliminates unnecessary weight and streamlines the unit to help prevent binding

Product Specifications

- Available Capacities:

- EDjr–1T – 2,500 lb | 1,000 kgf | 10,000 N

- EDjr–2T – 5,000 lb | 2,000 kgf | 20,000 N

- EDjr–5T – 10,000 lb | 5,000 kgf | 50,000 N

- EDjr–10T – 25,000 lbf | 10,000 kgf | 100,000 N

- Accuracy::

- 0.2% of capacity

- Display:

- 128 x 64 dot-graphic LCD display shows all digits

- 1.0″ (26 mm) high plus annunciators and softkeys

- Hook Choices:

- Basic Swivel Hook – Used to align rigging to the crane

- Non-Swivel Hook – Basic hook for low-cost, low-headroom weighing

- Includes:

- Carry case, batteries, manual and calibration card

Literature

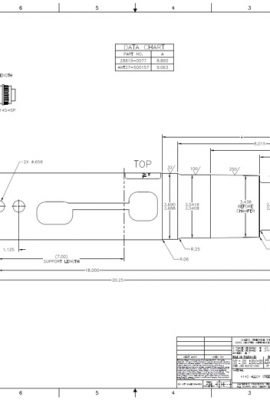

EDjunior Dynamometer

The EDjunior dynamometer gets straight to the point, apply a load – take a reading. Its Spartan design is a direct response to industries that have wanted an extremely well-built instrument that could be relied upon for simple, yet critical measurements of weight and force.

The EDjunior draws its strength from the exhaustive engineering that went into the design of the Dillon EDXtreme dynamometer. Both share the same base of research and testing to match material characteristics and load cell technology. The choices made in development have yielded an exceptionally rugged instrument capable of consistently delivering accurate, repeatable measurements.

The EDjunior is even more remarkable when you consider price. If you believe you have to pay more to get more – just compare the Dillon EDjunior to the competition. Nothing else comes close!

The EDjunior is all about value. Behind its simple design and easy operation, you will find the quality and performance not found elsewhere in the low price range. With the EDjunior, Dillon proves that economy can go hand-in-hand with accuracy, long service life and, most importantly, worker safety.

Click here to view product dimension

Click here to view available shackle dimensions

Click here to view available hook attachment dimensions

Product Features

- The EDjunior provides peak detection as well as sustained load readings

- The load element design and strain gauges chosen for the EDjunior produce an accuracy of 0.2 % (full scale)

- Readings are displayed with a resolution of 1 part in 1000 to ensure the level of readability required for critical lifting applications

- The exclusive Dillon SOFTKEY interface provides direct access to setup and display functions without the typical confusing menu structure

- With the EDjunior’s low power consumption, typical battery life is over 425 hours

- Dillon’s distinctive curve-body design further eliminates unnecessary weight and streamlines the unit to help prevent binding

Product Specifications

- Available Capacities:

- EDjr–1T – 2,500 lb | 1,000 kgf | 10,000 N

- EDjr–2T – 5,000 lb | 2,000 kgf | 20,000 N

- EDjr–5T – 10,000 lb | 5,000 kgf | 50,000 N

- EDjr–10T – 25,000 lbf | 10,000 kgf | 100,000 N

- Accuracy::

- 0.2% of capacity

- Display:

- 128 x 64 dot-graphic LCD display shows all digits

- 1.0″ (26 mm) high plus annunciators and softkeys

- Units of Measure:

- pound-force

- kilogram force

- Newtons

- Includes:

- Carry case, batteries, manual and calibration card

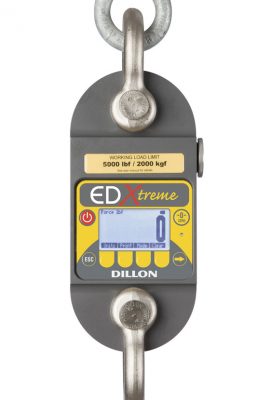

EDXtreme Dynamometer

The EDXtreme exemplifies the trademark precision and rugged construction of Dillon dynamometers. Its highly refined design draws on the inherent strengths of premium grade materials to achieve a 5:1 minimum factor of safety.*

While the EDXtreme may be configured for something as simple as a digital hanging scale, it offers a higher level of intelligence. With user-defined functions and sophisticated communication options, the EDXtreme readily adapts to multi-tasking operations or multi-link systems capable of monitoring a series of critical stress points from a single location. It is the definition of application versatility.

Building a precision instrument that can survive real-world punishment requires masterful engineering. This is where Dillon’s experience shines through. The engineers assigned to the EDXtreme drew on a depth of industrial application knowledge and conducted exhaustive materials testing to achieve the highest structural integrity.

One of the foremost reasons for choosing an electronic dynamometer is added functionality. The radio or hardwired options available with the EDXtreme offer the convenience and safety of remote operation. Additionally, data from the dynamometer(s) can be downloaded to a PC via an RS-232 connection for compilation and analysis or to generate hard-copy printouts.

The optional Communicator is an extremely powerful hand-held remote that can define the function and manage the operation of one or more EDXtreme dynamometers using wired or radio technologies. Through the programmable SOFTKEY interface, one or more Communicators can monitor multiple dynamometers within the same airspace. In multiple-link lifting arrays, the Communicator can display readings at any or all lift points and calculate the total load.

Since 1937, Dillon Dynamometers have been chosen for the jobs where only the best will do. Now, Dillon has once again lifted the performance bar and set the standard for others to follow.

* Models with 75 T/160,000 lb or higher capacity feature a 4:1 safety factor and 0.3% accuracy.

Click here to view product dimension

Click here to view available shackle dimensions

Click here to view available hook attachment dimensions

Product Features

- High capacity models are constructed of powder coated aircraft-quality alloy steel

- Lower capacity models are powder coated aircraft-quality aluminum

- On board storage (accumulation lift and store, push button, and continuous)

- Allows the use of custom units of measurement along with multiple lines or reeving

- Programmable functions can correct for gravitational variations

- Wide-angle, backlit LCD provides improved readability over a wider viewing angle and low light conditions

- Powered by two easily accessible standard C-cell batteries

- LED light load alarm

Product Specifications

- Available Capacities:

- EDX–1T – 2,500 lbf | 1,000 kgf | 10,000 N

- EDX–2T – 5,000 lbf | 2,000 kgf | 20,000 N

- EDX–5T – 10,000 lbf | 5,000 kgf | 50,000 N

- EDX–10T – 25,000 lbf | 10,000 kgf | 100,000 N

- EDX–25T – 55,000 lbf | 25,000 kgf | 250,000 N

- EDX–50T – 100,000 lbf | 50,000 kgf | 500,000 N

- EDX–75T – 160,000 lbf | 75,000 kgf

- EDX–100T – 220,000 lbf | 100,000 kgf

- EDX–150T – 330,000 lbf | 150,000 kgf

- EDX–250T – 550,000 lbf | 250,000 kgf

- Accuracy:

- 0.1% of capacity up to EDX-50T*

- 0.3% of capacity for EDX-75T and above*

- Display:

- 128 x 64 dot-graphic LCD display shows up to 6 digits 1.0″ (26 mm) high

- Digits are .11 inches (3 mm) thick for unmatched readability

*Normal resolution mode with Dillon provided shackles

FLSC Advanced Digital Forklift Scale System

This advanced digital scale features a wireless carriage option, which makes it tougher, smarter and safer than other designs.

The FLSC forklift scale is a market leading system which turns an ordinary class II forklift truck into a mobile scale.

Tougher Forklift scale

The forklift scale’s extremely robust design has two metal plates, coupled together with Weigh Bar weight sensors. Not only does this mean no springs or flexures to break, but the system can be easily dismantled and moved to another truck in minutes, if needed.

Smarter Forklift scale system

The wireless scale option eliminates the need for a cable to the in cab weight indicator. This suits triple-mast forklifts and stock pickers or environments where the standard coiled scale/instrument cable may be easily damaged.

Safer to operate

The forklift scale mounts directly on the forklift truck carriage. It has a completely open center area, so the driver can clearly see the fork tips.

Legal for trade

The FLSC digital forklift scale is trade approved, making it suitable for use in applications where product is sold by weight.

Easy install

The FLSC can be easily retrofitted to your existing forklift fleet, minimizing downtime and making installation simple and straightforward.

Integrated Weight Indicators

Compatible with the FLI225 forklift scale weight indicator, which features a simple user interface to minimize operator confusion and error.

For a more advanced requirements, the FLI425 features a 7” full color, touchscreen display capable of displaying up to 19 data fields simultaneously.

Specifications

- FLSC Forklift Truck Scale System Specification Sheet (US)

- FLSC Forklift Truck Scale System Specification Sheet (Non US)

- Derating Forklift Capacity

FT12 Load Foot

The FT12 is a cost-effective load foot for use with shear beam load cells in applications such as platform scales.

Consisting of stainless steel and rubber (elastomeric) parts, it provides a stable base for the load cell and ensures the load is applied in an optimum manner. It is ideal for use in a general industrial environment.

Key features

- Capacity range: 300-2500kg

- Stainless steel and rubber (elastomeric) components

- M12 connection

- For use with shear beam load cells T85 and T85-N

Typical applications:

- Multi-cell platform scales

Literature

General Purpose Platform Scale – ZM110

The ZM110 Digital Bench Scale is a battery operated bench and indicator system that offers general weighing, checkweighing and check counting with an easy-to-use interface. The ZM110 can be supplied as a trade approved bench scale system at 3,000 divisions as well as 6,000 divisions for applications where trade approval is not required. As a system, the base combines with a pole-mounted indicator that can be used for a wide range of general purpose floor or bench base type applications.

Robust base construction

With 150% overload protection, powder coated tubular base frames constructed of mild steel, with four corner stops the load cell are well-protected.

Anti-slip feet

The base frame is fitted with four large, lockable, adjustable anti-slip feet ideal for leveling the base if positioned on uneven ground.

Top quality load cell

The NSF ANSI3A certified, fully stainless steel Diamond bases are IP69K rated, making them ideal for heavy washdown environments, particularly in the food and beverage industries.

Food grade top pan

The base is fully covered with a removable, hard-wearing, food grade 304 stainless steel top pan.

Easy-to-read indicator

The ABS housed Avery Weigh-Tronix ZM110 Indicator has a large, easy-to-read 50 mm x 165 mm LCD backlit display with 40 mm high digits

Battery powered weighing

The built-in battery allows this product to be used in low lit areas or in areas where power outlets are hard to find. The ZM110 can provide over 107 hours of battery life between charges.

Application

General weighing in both kg, lb, Pieces, Basic Counting, Check Counting, Checkweighing.

General Weighing: Designed to weigh in lb, kg, or pieces, the ZM110 can easily be set into sample mode – ideal for counting a wide range of medium sized components.

Checkweighing & Check Counting: Ideal for guaranteeing product or box quantities are within an agreed weight or count size and for repetitive packing applications, the ZM110 easily switches between operating applications.

Technical specification

Bench sizes

400 mm x 400 mm

400 mm x 500 mm

500 mm x 600 mm

Capacities, Resolutions & Base Dimensions (L x W)

6000d unapproved

400 mm x 400 mm base – 60 kg x 0.01 kg

400 mm x 500 mm base – 150 kg x 0.02 kg

400 mm x 500 mm base – 300 kg x 0.05 kg

500 mm x 600 mm base – 300 kg x 0.05 kg

3000d EC approved E2 Stamped

400 mm x 400 mm base – 60 kg x 0.02 kg

400 mm x 500 mm base – 150 kg x 0.05 kg

400 mm x 500 mm base – 300 kg x 0.1 kg

500 mm x 600 mm base – 300 kg x 0.1 kg

Minimum and Maximum Load Cell Impedance

87 to 1100 ohms

Unit of Measure

Allows up to two units of measure plus piece counting (kg, pounds, grams, pounds/ounces). Primary unit of measure kg.

Capacity Selections

Configurable 999,999 with decimal located zero to five places

Division increment

1 to 50 in multiples and sub-multiples of 1, 2, 5

Auto Zero Tracking

Configurable +/- 0 to 5 divisions

Operational Keys

Eight operation keys (Unit, Select, Print, Zero, Tare x 2, On, Off). Two functional tare keys to accommodate both left and right hand dominant operators.

Operating Temperature

-10° to 40° C

Operating Humidity

10 to 90% relative humidity, non-condensing

GL Force Gauge

The Dillon GL Force Gauge is the best equipped force gauge found in its price range, including features such as rechargeable battery, serial output, backlight, die-cast enclosure, carry case and more. The GL is available in a wide assortment of capacities to fit nearly any testing need.

The optional CT Test Stand is an ideal complement to the GL Force Gauge to improve testing results. Dillon also offers a range of grips and accessories to expand testing possibilities.

Product Features

- Measures tension and compression forces

- Rechargeable battery for portability

- Backlit display for all light levels

- Serial output to transmit data

- Includes full set of handy accessories

Product Specifications

- Available Capacities:

- GL025 – 5.5lb/25N/2.5kg

- GL050 – 11lb/50N/5kg

- GL100 – 22lb/100N/10kg

- GL250 – 55lb/250N/25kg

- GL500 – 110lb/500N/50kg

- Accuracy:

- ± 0.4% of capacity

- Display:

- 7 segment LCD, 4.5 digits with backlight

- Power:

- Rechargeable battery or AC charger

- Includes:

- Hook, plate, cone point, chisel, inverted chisel, extension rod, carry case, batteries, charger, user’s manual, calibration card

Literature

Junction Boxes

With Thames Side’s versatile range of junction boxes, load cell connection problems are solved simply and cost-effectively.

Our models include:

- Standard ABS junction boxes for 4 or 8 load cells, with or without trimming potentiometers for corner correction on platform scales etc.

- Versions with in-built lightning surge arrestors for truck scales or weighing in remote locations with a great lightning risk

- Stainless steel options

- Versions for digital load cells

- Special version for ATEX applications (all zones)

- Special version with real-time load cell condition monitoring – Intelligent Junction Box

The majority of our junction boxes have hermetic sealing that provides IP66 ingress protection.

To create a complete weighing system (measuring chain) the junction box must be connected to an indicator/transmitter etc. We offer specially designed durable polyurethane cable can be in custom lengths, in 4-wire or 6-wire configurations.

Key features

- 5 year warranty

- Robust, high quality design

- Lightning surge arrestors available

- ATEX version available for all zones (0, 1, 2, 20, 21, 22)

- IP66 protection

- Intelligent version available

Literature

LA66 Anti-Vibration Assembly

The LA66 is an anti-vibration weighing assembly, designed for use with the T66 bending beam load cell. Its purpose is to reduce the effects of unwanted forces and vibrations on the output signal of the load cell.

It consists of a stainless steel base plate mounted underneath the T66 load cell, with a rubber “silent block” pad mounted above the T66, connecting it to the structure being weighed. All metallic hardware is stainless steel.

Protection against vertical overload is easily achieved, by setting the adjustable stop mounted in the baseplate.

When combined with the T66 load cell (ordered separately) it is an ideal solution for high accuracy weighing of hoppers, tanks and mixers experiencing movement/vibration during operation, especially legal-for-trade applications in harsh environments. ATEX options are also available for hazardous areas.

Key features

- Very easy to install

- Capacity range 5kg to 300kg

- Designed for platform, hopper, tank and mixer scales with vibration

- T66 load cell is OIML approved to 3000 divisions (C3) or 6000 divisions (C6)

Fully welded and hermetically sealed stainless steel construction

Protection class IP68/IP69K

Typical applications:

- Platform scales

- Weighing with a mixer or agitator

- Big bag (FIBC) filling

- Belt scales and conveyors

- Tank and vessel weighing

- Systems using a screw feeder or screw conveyor

Literature

LA66 Tension

The LA66 Tension accessory provides a simple way to apply a tensile load to a T66 bending beam load cell, allowing tension measurement from 5kg up to 300kg load cell capacity with OIML C3/C6 approval and IP68/IP69K ingress protection. The mounting blocks and articulating rod end bearings are manufactured from corrosion resistant zinc plated steel.

An ATEX option on the T66 load cell is also available for hazardous areas.

Key features

- Easy to install

- Capacity range 5kg to 300kg

- OIML approved load cell: C3 at capacity 10-300kg or C6 at capacity 50-250kg

- Fully welded and hermetically sealed stainless steel load cell, with protection class IP68/IP69K

- Zinc plated mounting blocks and rod end bearings

- Option: Parylene coating for the T66 load cell when used in extremely harsh environments, as well as a version for high temperature use

Typical applications:

- Force measurement applications

- Low capacity tension applications

Literature

LA85 Anti-Vibration Assembly

The LA85 is an anti-vibration weighing assembly, designed for use with the T85 (or T85-N) shear beam load cell. in harsh industrial environments. It is designed to prevent unwanted forces and vibrations from affecting the output of the load cell.

It consists of a stainless steel base plate mounted underneath the T85 load cell, with a natural rubber “silent block” pad mounted above the T85, connecting the load cell to the structure being weighed. All metallic hardware is stainless steel.

When combined with the T85 load cell (ordered separately) it is an ideal solution for high accuracy weighing of hoppers, tanks and mixers experiencing vibration during operation, especially legal-for-trade applications in harsh environments. An ATEX option is also available for hazardous areas.

The LA85 anti-vibration assembly replaces the previous LA350 anti-vibration assembly.

Key features

- Very simple to install

- Capacity range 300kg to 5000kg in 3 sizes: 300kg-2500kg ; 3000kg-5000kg ; 7500-10000kg

- Designed for platform, hopper, tank and mixer scales with vibration

- T85 load cell is OIML approved to 3000 divisions (C3)

- T85 load cell has a fully welded and hermetically sealed stainless steel construction, with protection class IP68/IP69K and calibrated in mV/V/Ohm

- Option: ATEX approval, Parylene coating for the T85 load cell when used in extremely harsh environments, as well as a version for high temperature use

Typical applications:

- Platform scales

- Mixers

- Big bag (FIBC) filling

- Belt scales and conveyors

- Tank and vessel weighing

- Applications involving screw feeders

Literature

LeverMount®

The LeverMount® is a unique, patented and cost-effective solution for process weighing in harsh environments.

Installation is easier, safer and faster using this simple innovative design.

It combines a 316 stainless steel mounting accessory with an OIML approved load cell (bending beam or shear beam) protected to IP68 and IP69K, creating an ideal solution for legal-for-trade weighing applications requiring wash-down cleaning, even in hazardous (ATEX) areas.

Separate lifting equipment (such as a hydraulic jack or lifting tool) is NOT required to raise and lower the weighing vessel, even if the vessel is full – therefore the installation is very simple and fast. And the manufacturing process does not need to stop if a load cell must be changed in the future.

The 3-point base mounting provides excellent mechanical stability with no need for shims.

We supply the LeverMount® mounting accessory locked in position. The load cell can remain safely in its packaging until the mechanical installation (and any necessary welding) is complete, thus avoiding potential damage. The LeverMount® transit bolts are then removed and the same bolts are used to secure the load cell in position; in this way the load cell acts as a lever to raise the upper plate of the mounting accessory into the weighing position, no matter whether the vessel is empty or full.

Removal and re-installation of a load cell is simple and very fast.

The LeverMount® is available in 2 versions:

– A standard version (which uses a hardened load button and saddle) for static applications such as tank and hopper weighing

– A special self-centering (SC) version (which uses a ball-and-cup kit up to 2500kg capacity, or a spherical-ended-pillar-and-cup kit at 3000kg & 5000kg capacities) for ‘dynamic’ applications such as platform scales, or conveyor scales with an end stop (when self-centering of the mounting accessory is required due to repetitive movements)

Key features

- Capacity range 5-5000kg in 3 body sizes; uses T66 or T85load cell

- NEW capacity: 2500kg using mid-size accessory (300kg-2500kg capacity range)

- Mounting accessory is 316 stainless steel

- No requirement for separate lifting equipment, such as a hydraulic jack

- Vessel can remain full when a loadcell is fitted or removed: minimum production down-time

- Shims are not required, due to the 3-point base mounting

- Load cells are fully welded and hermetically sealed to IP68/IP69K

- T66 load cell: approved to OIML R60 C3 (3000 divisions) or C6 (6000 divisions)

- T85 load cell: approved to OIML R60 C3 (3000 divisions) and calibrated in mV/V/Ohm for faster setup

- ATEX option for use in all zones (no need for safety barriers in dust zones 20, 21 and 22)

- Optional high temperature version of T66/T85 load cell, for use up to +150 °C (continuous)

Typical applications:

- Hopper and tank weighing, even in harsh ‘wash-down’ environments

- Platform scales or conveyor scales with an end stop (using the self-centering version)

Literature

Load Cell Connection Cable

Almost all Thames Side load cells are supplied with a high specification, blue Polyurethane sheathed cable. This provides the load cell with excellent environmental protection to maintain the integrity of the weighing system.

Special Polyurethane load cell connection cable can be supplied to connect from the junction box to the instrumentation/electronics, in custom lengths of up to 200 metres. It is available in a 4-core or 6-core configuration, each with a screen.

The Polyurethane sheath is halogen free and extremely tough, with a high resistance to rodent bites, cuts from sharp objects or tools, strong chemicals, UV radiation and offshore oil drilling ‘mud’.

This special cable is particularly well suited to harsh environments in food processing industries, such as slaughterhouses, meat and fish processing factories, where daily wash-down of equipment is very common.

Key features

- For connections between junction box and weighing electronics

- Durable, rugged Polyurethane sheath (halogen free)

- Screened 4-core or 6-core options

- High toughness and resistance to cuts, strong chemicals, UV radiation and offshore oil drilling ‘mud’

- Rodent resistant

Literature

Load Cell Simulator

The LCS-3 load cell simulator is an excellent tool for pre-calibrating load cell systems before installation, or for checking the performance of a load cell or weight indicator during troubleshooting activity. It provides a mV/V output that can be set by the operator to simulate the changing signal from a load cell as the weight varies.

This model is characterised by low drift, high accuracy (typically +/- 0.025%) with good thermal stability (25 ppm/°C). It offers several features such as a switch for +/- polarity, the option to change the output in discrete steps or continuously, with an operation LED to show the unit is receiving an excitation voltage from the weighing electronics.

For simulation of the effects of safety barriers in hazardous applications, a +/- sense switch is also available.

Key features

- Passive device

- Low drift, high accuracy

- LED to indicate excitation from electronics

- +/- polarity and +/- sense switches

- 0-3 mV/V signal range in discrete steps

- Continuous -2 to +2 mV/V signal range

- Setting for 1/2/3/4 load cells

- Resistance equal to 350 ohm load cell

Literature

Load Cell Tester

The LCT-U can quickly diagnose problems with all common types of strain gauge load cell available, including 6-wire load cells (with sense wires). It is a stand-alone, hand-held device specially designed for fast, comprehensive troubleshooting.

It immediately provides the operator with all essential data about the load-cell being tested, including the bridge resistance and integrity, physical distortion (possibly caused by overload, shock load or metal fatigue) and insulation resistance (which can highlight moisture or chemical ingress due to casing or cable damage). Errors are clearly shown by a red LED illuminating.

Key features

- Fast, accurate testing within just 5 seconds

- Coloured LEDs highlight suspicious readings

- Can check for physical distortion of a load cell

- Lightweight and powered using 4 x AA batteries (not included)

- Ideal tool for installation/commissioning engineers

Literature

MasterMount®

The MasterMount® is a unique, patented and cost-effective load cell/mounting accessory combination for silo, tank, hopper or vessel weighing. Installation is made easier, safer and much faster using this simple innovative design. Load cell installation/replacement can be carried out in only a few minutes.

A high precision stainless steel VC3500 double shear beam load cell, protected to IP68/IP69K, combines with a painted alloy steel weighing module having an integrated cam mechanism. This is an ideal combination for applications requiring wash-down cleaning, even in hazardous (ATEX/IECEx) areas. The load cell’s ATEX certification eliminates the need for safety barriers in dust zones 20, 21, 22.

No specialist tools or lifting equipment is necessary to raise the weighing vessel, install a load cell, then lower the vessel again – even when it is full. The lifting and lowering is carried out by the weighing module itself. This reduces the list of tools required for installation and increases safety.

This is a cost-effective solution, designed to simplify the installation work of weighing system integrators.

Because the MasterMount accessory is manufactured as a cast construction, it is exempt from any requirement for approval to EN 1090 / Construction Products Regulation.

The MasterMount® mounting accessory can be bolted to the feet of the silo, tank, vessel or hopper before this is delivered to its final location. The load cell can remain in its separate packaging until the mechanical installation (and any necessary welding) is complete, thus avoiding potential damage to the sensitive load cell. Then the cam mechanism is turned by 180 degrees to lower the top plate into the weighing position, even with up to 20,000kg of weight on each MasterMount – therefore production does not need to stop in the unlikely event of a load cell being changed. Removal of the load cell, for example to move the weighing vessel or for eventual load cell replacement after many years, is simply the reverse of the above.

Lift-off protection is achieved by the mounting accessory alone, so protection is available before load cell installation and there is no reverse shock loading transmitted to the load cell by uplift forces, for example heavy winds. Other mounting accessory designs can transmit reverse shock loading to the load cell.

Key features

- Load cell installation/removal under load, in just 1-2 minutes, without any lifting jacks or dummy load cells – minimal production downtime

- Low profile design

- Exempt from requirement for approval to EN 1090 / CPR

- Capacity range 2,000kg to 30,000kg with one size of load cell and mounting accessory

- Fully welded and hermetically sealed stainless steel load cell, protected to IP68/IP69K

- ATEX approved version for all zones (no need for safety barriers in dust zones 20, 21 and 22)

- IECEx approved version for all zones

- Options: Parylene coating for the load cell when used in extremely harsh environments, high temperature and amplified output (4-20mA) versions

Typical applications:

- Silo, hopper or tank weighing, even in hazardous areas

For another unique weighing solution at capacities from 5kg to 5000kg the LeverMount® combination of a stainless steel mounting accessory and an OIML approved shear beam load cell is ideal.

Literature

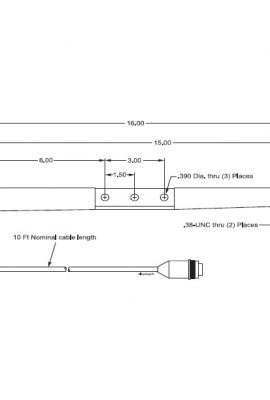

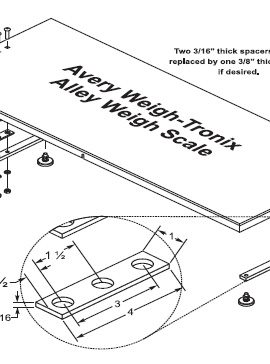

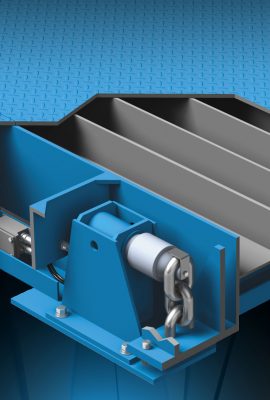

MaxDec High Capacity Floor Scale

The MaxDec heavy duty floor scale is designed for high traffic and high capacity weighing up to 100,000 lbs.

This platform scale is engineered to be especially strong, making it suitable for the most demanding of industrial weighing applications.

Unique design for improved accuracy and durability

The MaxDec floor scale’s design features a unique chain link suspension using patented Weigh Bar weight sensing devices.

The chain link absorbs shock loads and end loads, resulting in improved accuracy and durability.

Built for continuous use

The MaxDec platform scale has high strength 4.4” steel deck plates welded to internal steel channels to reinforce the scale.

This allows the floor scale to withstand continuous or high capacity use with minimal downtime.

This platform scale is engineered to be especially strong, making it suitable for the most demanding of industrial weighing applications.

Model X-C

Model X-C comes in nine capacities ranging from 50 lb to 25,000 lb or 50 to 10,000 kg. All feature accuracy of ±1% of full capacity, except the 25,000 (10,000 kg) capacity instruments which are accurate to ±2% of full capacity.

Load is applied against a hardened ball which rotates to maintain vertical alignment as pressure increases. The ball is held in place with a spring clip or retainer. A threaded mounting hole is located opposite the loading ball in the bottom of the beam.

Model X-C is available in pound and kilogram capacities.

Options:

- Shockless dial indicator for installations involving the sudden application or release of force. (Maximum pointer cannot be supplied with shockless dial indicator)

- Maximum load pointer which remains at peak load until manually reset.

- Zero position on dial may be factory positioned at 12, 3, 6, or 9 o’clock. Standard position is at 12 o’clock.

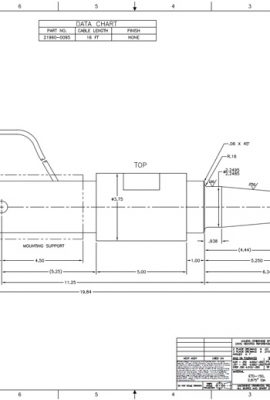

Click here to view product dimension (Page 1)

Click here to view product dimension (Page 2)

Literature

Model X-PP

Force gauges calibrated in push-pull are available in four capacities in pounds ranging from 50-0-50 lb up to and including 2,500-0-2,500 lb and three metric capacities from 50-0-50 to 1,000-0-1,000 kg. Accuracy is ±2% of maximum dial reading (based upon total capacity of both compression and tension scales).

Model X-PP gauges in capacities up to and including 500-0-500 lb or 250-0-250 kg are supplied with a set of self-aligning spherical rod-end connectors for tension loading. Force is applied to connectors through a hardened steel pin which must be slip fit in connector holes.

2,500-0-2,500 lb and 1,000-0-1,000 kg capacity gauges are equipped with two shackle adapters, shackles and pins. Shackles must be removed when compression load is involved. Force is then applied against shackle pins in a suitable test setup.

All push-pull gauges are supplied with a compression-loading spherical ball fitting for compression loading.

Options:

- Shockless dial indicator for installations involving the sudden application or release of force. (Maximum pointer cannot be supplied with shockless dial indicator)

- Zero position on dial may be factory positioned at 12, 3, 6, or 9 o’clock. Standard position is at 12 o’clock.

Click here to view product dimension (Page 1)

Click here to view product dimension (Page 2)

Literature

Model X-ST

Dillon offers the Model X-ST in seven capacities from 100 lb to 10,000 lb or 25 kg to 5,000 kg. Accuracy is ±1% of full range. (Note: For applications requiring capacities beyond 10,000 lb or 5,000 kg in tension, consider the Dillon Dynamometer).

Tension Force Gauges in capacities through 2,000 lb (1,000 kg) are supplied with two rod-end connectors. 5,000 and 10,000 lb (5,000 kg) capacities are equipped with convenient shackles and pins.

Calibration is available in pounds and kilograms.

Options:

- Shockless dial indicator for installations involving the sudden application or release of force. (Maximum pointer cannot be supplied with shockless dial indicator)

- Maximum load pointer which remains at peak load until manually reset.

- Zero position on dial may be factory positioned at 12, 3, 6, or 9 o’clock. Standard position is at 12 o’clock.

Click here to view product dimension (Page 1)

Click here to view product dimension (Page 2)

Literature

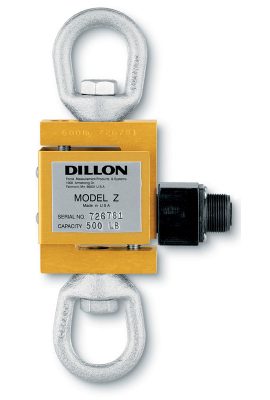

Model Z

Dillon offers a wide range of popular S-Beam and canister load cells to match specific application needs. A large assortment of connecting hardware makes this combination even more versatile. Combine several load cells together to see their combined output with a load cell summing box. Two year warranty.

Receive free calibration when you couple a Dillon load cell with any Dillon indicator.

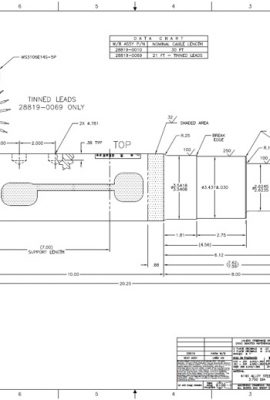

Click here to view product dimension

Click here to view product wiring diagram

Product Features

- Top-grade material

- Built in overload stops

- Includes hardware

Product Specifications

- Available Capacities:

- 25 / 50* / 100 lb | 10 / 22* / 45 kg

- 500 / 1,000 lb | 220 / 450 kg

*Compression only

Literature

Postal, Mail and Shipping Scales

Our range of post, mail and shipping scales are highly accurate, developed in partnership with our customers and designed for use in a range of environments, from retail counters to back office systems. Most are highly connective, able to integrate into existing pos and data systems.

They can stand up to a busy day in the post office or mail room, day after day, and still discern very small differences in weight. The postal scale range features easy to use operator displays, for error free, rapid customer service.

Avery Weigh-Tronix boasts an extensive range of industrial products applicable to the postal logistics industry that can enhance productivity and optimise revenue. Click here to find out more

Prescription Dispensing Automation – Eyecon 9420

Simplify your pill counting and inventory management.

The Eyecon® with Visual Precision Counting, eliminates the burden of prescription filling with a 99.99% count accuracy.

Eliminate over-dispensing and increase efficiency

For most pharmacies, Eyecon pays for itself in just a short time. Eliminate over-dispensing, reduce count times and time spent on physical inventory so you can spend more time with customers and feel confident that your prescriptions are being filled correctly.

QTLTSC Forklift Scale for Class III Forklifts

The QTLTSC forklift scale allows your forklift truck to weigh loads without disrupting your normal routine.

These robust scales are suitable for Class III and Class IV forklift trucks where trade approved weighing is required, making them suitable for use where product is sold by weight. This scale is certified legal for trade in the US only.

Extremely durable design

The QTLTSC forklift scales are extremely durable and proven to stand up to busy environments.

The scale’s design features two metal plates coupled together by Weigh Bar weight sensors. This design means no flexures, springs or hydraulics to break down, maximizing uptime.

Easy to use interface for simple data management

Compatible with the FLI225 forklift scale weight indicator, which features a simple user interface to minimize operator confusion and error.

For a more advanced requirements, the FLI425 features a 7” full color, touchscreen display capable of displaying up to 19 data fields simultaneously.

Easy to fit

The forklift scale is attached to the existing forklift carriage and uses the forklift’s stock forks. If needed, the scale and instrument system can be moved to another truck in minutes.

ITA Class III Cleat Type

- 5,000lb x 5lb / 2,500 x 2kg

- 10,000 x 10lb / 5,000 x 5kg

Specifications

QTLTSC Forklift Scale for Class IV Forklifts

The QTLTSC forklift scale allows your forklift truck to weigh loads without disrupting your normal routine.

These robust scales are suitable for Class III and Class IV forklift trucks where trade approved weighing is required, making them suitable for use where product is sold by weight. This scale is certified legal for trade in the US only.

Extremely durable design

The QTLTSC forklift scales are extremely durable and proven to stand up to busy environments.

The scale’s design features two metal plates coupled together by Weigh Bar weight sensors. This design means no flexures, springs or hydraulics to break down, maximizing uptime.

Easy to use interface for simple data management

Compatible with the FLI225 forklift scale weight indicator, which features a simple user interface to minimize operator confusion and error.

For a more advanced requirements, the FLI425 features a 7” full color, touchscreen display capable of displaying up to 19 data fields simultaneously.

Easy to fit

The forklift scale is attached to the existing forklift carriage and uses the forklift’s stock forks. If needed, the scale and instrument system can be moved to another truck in minutes.

ITA Class IV Cleat Type

- 10,000lb x 10lb

- 16,000 x 20lb

Specifications

Quick Check-T Cell Tower Shunt Meter

The Dillon Quick Check-T tension meter makes a difference. It reduces time on the job site by eliminating the need for whiteboards, changing sheaves, and the need for charts to figure out target tensions. This unit also reduces time off of the job site by having automatic site form completion, with image, and direct complete reports.

Product Features

- Bluetooth® enabled

- Custom mobile app

- Multi-wire single sheave

- Calibration check rod

- Automatic report generation with photos

- Automatic target tension calculations

- Ability to capture pre and post tension readings

- Inbuilt image capture

Product Specifications

- Capacity:

10,000 lb/45 kN/4500 kg - Communications:

Bluetooth® - Data Export:

Via mobile app - Wire Calibrations:

Up to 20 wire calibrations - Capture Rate:

10Hz, 100Hz & 1000Hz - Accuracy:

+ 3% instrument capacity - Operating Range:

-4° F to 158° F (-20° C to 70° C) - Protection:

Hard polymer storage case included - Environmental:

Suitable for continued outdoor use - Weight:

11 lb (5 kg) - Size:

0 x 23 x 3” (25 x 59 x 8 cm) - Range:

Wire sizes from 3/16” (4.75 mm) up to 1.0” (25.4 mm) - Display:

Dot-graphic LCD display supports full text - Units of Measure:

lbf, kgf & Newtons - Resolution:

Low / med / high (5000 resolutions) - Battery:

Two C batteries - Calibration:

2 x AA battery’s with 120+ hours life (backlight off ) - Calibration:

Each wire rope is calibrated and is traceable to the National Institute of Standards and Technology. Certificate included with curve readings. Passes only with three consecutive confirming runs, with all points in specification. - Recalibration:

Every 12 months - Approved By:

Majority of cell tower owners

Quick-Check Tension Meter

The Dillon Quick-Check tension meter is the premier innovation in the cable tensioning industry. Nothing comes close to the absolute simplicity of design and accuracy. It is ideal for cable guardrails, guy lines and overhead wires. The digital load cell is rugged, highly repeatable and accurate.

The Dillon Quick-Check tension meter can be placed on a cable, measure its tension, and removed in under five seconds. There are no complex lookup tables or conversion charts – saving time and money.

The operator can quickly select from 20 pre-calibrated wire sizes and types stored in Quick-Check’s memory. The Quick-Check tensioning mode graphically displays the current and target tension control limits for extremely quick setting of line tension. Even the infrequent battery changes are quick.

The Quick-Check tension meter can be employed in many industries requiring proper and provable tensioning. Typical applications include cell towers, stack guy wires, pre-tensioned cable barriers, bridges, elevators, winch rope, overhead electric transit wires, fall arrest systems, aircraft arresting cables and utilities as well as many more.

Click here to view product dimension

For a full list of available wire/rope slings, please contact the factory.

Click here to download the Wire Size Library Chart

Product Features

- Store wire rope readings and export data (Ideal for tower data collection)

- Time saving check-tensioning mode

- Portable and rugged – Designed for outdoor use

- Built-in averaging saves time and eliminates errors

- Factory calibrated for up to 20 unique wire sizes and types

Product Specifications

- Tension capacities:

- 2000 lb/10 kN/1000 kg

- 10,000 lb/45 kN/4500 kg

- Wire sizes:

- 3/16 inch through 1 inch (4.75 mm through 25.4 mm)

- Accuracy:

- ± 3% instrument capacity (calibrated to specific wire size and type)

- Display:

- Dot-graphic LCD display supports full text and 1 inch high digits

- Units of Measure:

- pound-force

- kilogram force

- Newtons

S-Beam

Dillon offers a wide range of popular S-Beam and canister load cells to match specific application needs. A large assortment of connecting hardware makes this combination even more versatile. Combine several load cells together to see their combined output with a load cell summing box. Two year warranty.

Receive free calibration when you couple a Dillon load cell with any Dillon indicator.

Click here to view product dimension

Click here to view product wiring diagram

Product Feature

- Measures both tension and compression

- Alloy steel with nickel plating

- Broad assortment of hardware

Product Specifications

- Available Capacities:

- 50 / 100 / 200 lb | 22 / 45 / 90 kg

- 500 / 1,000 / 2,000 lb | 220 / 450 / 900 kg

- 5,000 / 10,000 lb | 2,200 / 4,500 kg

- 20,000 lb | 9,000 kg

Literature

T11 Single Point

The T11 single point load cell is manufactured from high quality nickel plated alloy steel and its design provides for high accuracy weight measurement, even with off-centre loads.

It is suitable for platforms of size 500mm x 500mm maximum (with the load cell installed centrally under the platform) and carries OIML C3 approval (3000 divisions) from 15kg to 75kg capacities. Potted and silicone sealed to provide IP66 protection, it also features a polyurethane cable as standard. Polyurethane has a high resistance to UV radiation, temperature changes and impacts/cuts compared with PVC cable.

Key features

- Capacity range: 15-150kg

- High quality nickel plated alloy steel, corrosion resistant

- OIML C3 approval (15kg to 75kg capacities)

- Fully potted and sealed to IP66

- 500 x 500mm max. platform size (with load cell placed centrally under platform)

- Polyurethane cable

Typical applications:

- Small platforms up to 500mm x 500mm

- Small buckets and hoppers

- Bagging and dosing systems

- Checkweighers

- Big bag (FIBC) filling

Literature

T12 Single Point

The T12 single point platform load cell is manufactured from stainless steel and its design provides for high accuracy weight measurement, even with off-centre loads and in harsh environments.

Its hermetically sealed and fully welded construction, with protection class IP68/IP69K, is essential for use in applications involving regular wash-down at high temperatures and pressures, such as the food and pharmaceutical industries.

With OIML C3 approval (3000 divisions) and a screened 6-wire polyurethane cable this load cell offers high accuracy and insensitivity to electrical noise.

As an option, ATEX approval is available for use in hazardous areas where an explosion risk exists. For gas zones 20, 21 and 22 the ATEX certification does not require the use of safety barriers.

Key features

- Capacity range: 15-400kg

- High accuracy with off-centre loads

- Stainless steel, fully welded and hermetically sealed, protected to IP68/IP69K

- Complies with OIML R60 regulations up to 3000 divisions (C3) for scales according to EN 45501

- Small sensitivity tolerance of ± 0.1 % mV/V as standard

- 600mm x 600mm, or 800mm x 800mm, max. platform size (with load cell placed centrally under platform)

- Polyurethane cable

- Option: ATEX approval

- Optional high temperature version for use up to +150 °C

Typical applications:

- Weighing platforms up to 800mm x 800mm

- Bagging, filling and dosing systems

- Checkweighers

- Small buckets and hoppers

- Big bag (FIBC) filling

- Medical scales

- Hazardous (ATEX approved) weighing requirements

Literature

T12A Single Point

The T12A single point platform load cell is manufactured from high quality nickel plated alloy steel and its design provides for high accuracy weight measurement, even with off-centre loads when the environment does not require stainless steel.

Its potted and silicone sealed construction, protected to IP66, provides a cost-effective solution that is approved to OIML C4 (4000 divisions). As standard, the T12A is supplied with a screened polyurethane cable; this provides a higher level of resistance to cuts and damage than a PVC cable.

Key features

- Capacity range: 50-400kg

- High accuracy with off-centre loads

- Nickel plated alloy steel load cell, protected to IP66

- Complies with OIML R60 regulations up to 4000 divisions (C4) for scales according to EN 45501

- 600mm x 600mm, or 800mm x 800mm, max. platform size (with load cell placed centrally under platform)

- Polyurethane cable

Typical applications:

- Weighing platforms up to 800mm x 800mm

- Bagging, filling and dosing systems

- Checkweighers

- Small buckets and hoppers

- Big bag (FIBC) filling

- Medical scales

Literature

T16 Fluid Damped

The T16 single point fluid damped platform load cell is a reliable, simple, high precision and low cost solution for dynamic weighing applications, even with off-centre loading. The internal fluid damps the vibrations of the sensing element, offering faster settling times, increased weighing speeds and increased load cell life when compared to a non-damped load cell. It is therefore ideal for high speed check weighing and filling machines.

The internal aluminium sensor element is surrounded by a grade 316 stainless steel housing that is protected to IP68 by a special venting kit – allowing for wash-down in harsh environments that require regular cleaning. Its maximum operating temperature is a high 70 °C.

The excellent durability of this load cell comes from its integrated on-centre overload protection, with a dual stop providing bi-directional protection from upwards and downwards overload.

It is approved to OIML C4 (4000 divisions) as standard, with a durable screened polyurethane cable; this provides a higher level of resistance to chemicals, UV radiation, cuts and damage than a PVC cable.

Key features

- Capacity range: 5-35kg

- High accuracy and fast settling time with off-centre dynamic loads

- Bi-directional overload protection

- Complies with OIML R60 regulations up to 4000 divisions (C4) for scales according to EN 45501

- Viscous damped aluminium alloy sensing element; 316 stainless steel housing

- IP68 protection

- 500mm x 500mm, max. platform size (with load cell placed centrally under platform)

- Durable polyurethane cable, ideal for wash-down environments

- 2 year warranty

Typical applications:

- High speed check weighing

- Form, fill, seal machinery

- High speed bagging, filling and dosing machines

- Dynamic weighing applications

Literature

T20 Compression Assembly

The T20 is a low cost, reliable, simple solution for silo, tank, hopper and vessel weighing, especially when point-to-point level measurement by weight (gravimetric level measurement) is the main requirement. It was designed for operation at extremes of temperature, with an operating range from -50 °C to +70 °C.

It combines a fully welded and hermetically sealed stainless steel compression disc load cell, protected to IP68/IP69K, with a mounting accessory available in zinc plated steel or stainless steel. This is an ideal combination for applications in harsh environments that require regular wash-down cleaning.

The LA20 mounting accessory is extremely compact, with integral jacking to allow for fast, simple load cell installation and removal, as well as lift-off prevention and tolerance of angular misalignment. The underside of the top plate incorporates a hardened steel disc that provides for optimum load introduction.

As an option, ATEX approval is available for use in hazardous areas where an explosion risk exists. For gas zones 20, 21 and 22 the ATEX certification does not require the use of safety barriers.

Load cells can be fitted under all legs of the silo, vessel or hopper, but where cost is critical then dummy/false load cells (or pivot joints) can be fitted underneath one or more of the legs.

This is a cost-effective solution, designed with the needs of silo/tank manufacturers and weighing system integrators in mind.

Key features

- Fully welded and hermetically sealed stainless steel load cell, protected to IP68/IP69K

- Very low profile (low height) design

- 1000 division accuracy for cost efficiency

- Integral lift-off prevention and jacking

- Capacity range 1,000kg to 30,000kg in two sizes of load cell and mounting accessory

- Wide operational temperature range: -50 °C to +70 °C

- Option of Parylene coating for the load cell when used in extremely harsh environments

- Optional ATEX approval

- Optional high temperature version for use up to +150 °C

Typical applications:

- Silo, hopper and tank weighing

- Gravimetric level measurement

Literature

T301X Digital Load Cell

The T301x is a high capacity, highly accurate digital load cell suitable for use in weighbridge and hopper weighing applications in extreme environments.

It is hermetically sealed to IP69k, making it ideal for use in food and quarry applications, or monsoon regions where flooding is common.

Durable and robust load cell

The T301x load cell features all stainless steel construction, with the weighing element being manufactured from a solid piece of aircraft-quality stainless steel alloy.

The top and bottom load buttons are fully gaitered and pre-greased to help reduce wear from dust and moisture.

Highly accurate weight readings even in the toughest environmental conditions

TheT301X uses eight load-measuring gauges to guarantee consistently high accuracy, even when the load cell is operating at 3 degrees off centre.

Legal for trade load cell, available in a range of high capacities

Accurate to 5,000 and 6,000 divisions, the T301X carries OIML R60 trade approvals and is available in 30 and 45 tonne capacities.

Specifications

- T301X digital load cell Specification Sheet (En)

- T301X digital load cell Specification Sheet (Chinese)

- T301X digital load cell Specification Sheet (India)

T302X Load Cell

The T302x is a high capacity, highly accurate load cell ideal for weighbridge and hopper weighing applications.

It is hermetically sealed to IP69k, for superior moisture ingress protection and features a compact design for use in new or existing applications.

Manufactured to thrive in harsh environments

The T302x also has four specialised surge arresters to help protect from lightning and high voltage surges.

It is manufactured from a solid piece of aircraft-quality stainless steel, for superior performance and longevity.

Legal for trade load cell, available in a range of high capacities

The T302x load cell is highly accurate, to 5,000 divisions and carries OIML R60 approvals.

The T302x load cell is available in 22.5 and 45 tonne capacities.

T66 Bending Beam

The T66 high precision stainless steel bending beam is a world class load cell and widely used in industrial weighing applications. It offers extremely high accuracy with OIML approval and can withstand harsh manufacturing environments.

It has OIML approval to 3000 divisions (C3) or 6000 divisions (C6) and ATEX approval for use in hazardous areas where an explosion risk exists. Its certification for dust zones 20, 21 and 22 does not require the use of safety barriers. The load cell is supplied as standard with a 6-wire configuration (with sense wires). An optional 4-wire version is available on request (OIML C3 only).

The most common end use industries are Food Processing, Pharmaceutical, Chemical and Bulk Handling, in applications such as high accuracy tank weighing, platform scales, packaging & filling machines, belt scales and mobile conveyors.

Key features

- Fully welded and hermetically sealed stainless steel construction, with protection class IP68/IP69K

- Complies with OIML R60 regulations up to 3000 divisions (C3) or 6000 divisions (C6) for scales according to EN 45501

- Nominal capacities: 5kg, 10kg, 20kg, 30kg, 50kg, 75kg, 100kg, 150kg, 200kg, 250kg, 300kg, 500kg

- Nominal capacities (C6 version): 50kg, 75kg, 100kg, 150kg, 200kg, 250kg

- 6 wire (with sense wires) configuration as standard

- Wide operational temperature range: -30 °C to +70 °C

- Options: Parylene coating for the load cell when used in extremely harsh environments, as well as a version for high temperature use

Typical applications:

- Platform scales

- Big bag (FIBC) filling

- Belt scales

- Tank weighing

- Filling and packaging machinery

- Mobile conveyors

Literature

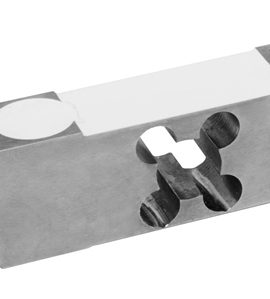

T85 Shear Beam

The T85 stainless steel shear beam is a high accuracy load cell that is widely used in industrial weighing applications worldwide. It has OIML approval (which is ideal in legal-for-trade applications) and it can withstand harsh manufacturing environments due to its fully welded and hermetically sealed design (IP68/IP69K).

It is suitable for a wide range of applications, thanks to its OIML approval to 3000 divisions (Class C3) and ATEX approval for use in hazardous areas where an explosion risk exists. For dust zones 20, 21 and 22 it has ATEX certification that does not require the use of safety barriers.

Capacities range from 300kg to 10,000kg (with a new capacity at 2,500kg).

For use in platform scales, the T85 load cell has optimised pre-corner adjustment, calibrated in mV/V/Ohm by output current matching at ± 0.05%. This reduces corner correction setup time to a minimum.

The most common end use industries are Food Processing, Pharmaceutical, Chemical and Bulk Handling.

This new T85 load cell replaces the previous model 350i load cell.

Key features

- Fully welded and hermetically sealed stainless steel construction, with protection class IP68/IP69K

- Complies with OIML R60 regulations up to 3000 divisions (C3) for scales according to EN 45501

- Nominal capacities: 300kg, 500kg, 750kg, 1000kg, 1500kg, 2000kg, 2500kg, 3000kg, 5000kg, 7500kg and 10,000kg

- Wide operational temperature range: -30 °C to +70 °C

- Options: ATEX approval, Parylene coating for the load cell when used in extremely harsh environments, as well as a version for high temperature use

Typical applications:

- Platform scales

- Big bag (FIBC) filling

- Belt scales and conveyors

- Tank and vessel weighing

Literature

T85-N Shear Beam

The T85-N low cost nickel plated steel shear beam is a high accuracy load cell that is widely used in industrial weighing applications where a fully welded and hermetically sealed stainless steel construction is not required. It has OIML C3 approval (which is ideal in legal-for-trade applications) and it is potted & silicone sealed to give IP66 protection.

For use in platform scales, the T85-N load cell has optimised pre-corner adjustment, calibrated in mV/V/Ohm by output current matching at ± 0.05%. This reduces corner correction setup time to a minimum.

This new T85-N load cell replaces the previous model 350n load cell.

Key features

- Nickel plated steel construction, silicone sealed to IP66

- Complies with OIML R60 regulations up to 3000 divisions (C3) for scales according to EN 45501

- Nominal capacities: 300kg, 500kg, 750kg, 1000kg, 1500kg and 2000kg

- Wide operational temperature range: -30 °C to +70 °C

- PVC cable

- 5 year warranty

Typical applications:

- Platform scales

- Big bag (FIBC) filling

- Belt scales and conveyors

- Tank and vessel weighing

Literature

T85-T Shear Beam

The T85-T stainless steel shear beam is a high accuracy load cell for industrial weighing applications, but primarily for platform scales due to its low height and blind loading hole, which introduces the load into the shear beam in the most optimum way. It has OIML C3 approval (which is ideal in legal-for-trade platforms) and it can withstand harsh working environments due to its fully welded and hermetically sealed design (IP68/IP69K).