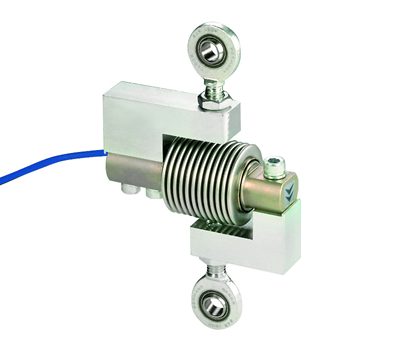

LeverMount®

The LeverMount® is a unique, patented and cost-effective solution for process weighing in harsh environments.

Installation is easier, safer and faster using this simple innovative design.

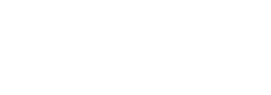

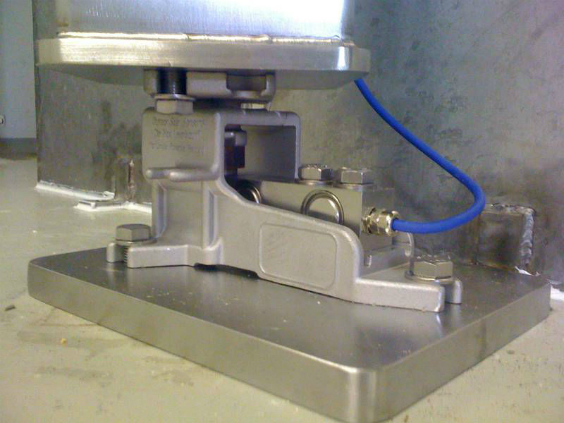

It combines a 316 stainless steel mounting accessory with an OIML approved load cell (bending beam or shear beam) protected to IP68 and IP69K, creating an ideal solution for legal-for-trade weighing applications requiring wash-down cleaning, even in hazardous (ATEX) areas.

Separate lifting equipment (such as a hydraulic jack or lifting tool) is NOT required to raise and lower the weighing vessel, even if the vessel is full – therefore the installation is very simple and fast. And the manufacturing process does not need to stop if a load cell must be changed in the future.

The 3-point base mounting provides excellent mechanical stability with no need for shims.

We supply the LeverMount® mounting accessory locked in position. The load cell can remain safely in its packaging until the mechanical installation (and any necessary welding) is complete, thus avoiding potential damage. The LeverMount® transit bolts are then removed and the same bolts are used to secure the load cell in position; in this way the load cell acts as a lever to raise the upper plate of the mounting accessory into the weighing position, no matter whether the vessel is empty or full.

Removal and re-installation of a load cell is simple and very fast.

The LeverMount® is available in 2 versions:

– A standard version (which uses a hardened load button and saddle) for static applications such as tank and hopper weighing

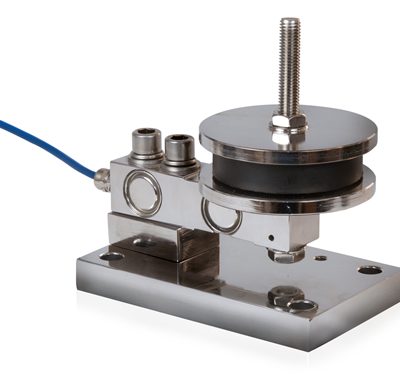

– A special self-centering (SC) version (which uses a ball-and-cup kit up to 2500kg capacity, or a spherical-ended-pillar-and-cup kit at 3000kg & 5000kg capacities) for ‘dynamic’ applications such as platform scales, or conveyor scales with an end stop (when self-centering of the mounting accessory is required due to repetitive movements)

Key features

- Capacity range 5-5000kg in 3 body sizes; uses T66 or T85load cell

- NEW capacity: 2500kg using mid-size accessory (300kg-2500kg capacity range)

- Mounting accessory is 316 stainless steel

- No requirement for separate lifting equipment, such as a hydraulic jack

- Vessel can remain full when a loadcell is fitted or removed: minimum production down-time

- Shims are not required, due to the 3-point base mounting

- Load cells are fully welded and hermetically sealed to IP68/IP69K

- T66 load cell: approved to OIML R60 C3 (3000 divisions) or C6 (6000 divisions)

- T85 load cell: approved to OIML R60 C3 (3000 divisions) and calibrated in mV/V/Ohm for faster setup

- ATEX option for use in all zones (no need for safety barriers in dust zones 20, 21 and 22)

- Optional high temperature version of T66/T85 load cell, for use up to +150 °C (continuous)

Typical applications:

- Hopper and tank weighing, even in harsh ‘wash-down’ environments

- Platform scales or conveyor scales with an end stop (using the self-centering version)

Literature